Sustainability is not only about recycling and clean air. Here at ALPLAindustrial we are committed to a global view of the topic. Sustainability, service and research do not each exist as a self-purpose, but intertwine and complement each other meaningfully. Constant ongoing development is essential and the best quality is vital.

Work in Progress

Recycling, sustainability and cradle2cradle stand for social

as well as ecological responsibility and WOLF PLASTIC takes its obligation in this regard seriously. ALPLAindustrial does not see an achieved goal here, but rather the future and many further goals that we can set ourselves. Our mission is not accomplished. Quite the contrary, it is only just beginning to take shape.

Modifications – step by step

ALPLAindustrial is fully aware of its responsibility to mankind and the environment. There are currently ongoing changes in the sensitive area of “Plastic Packaging” and we always try to be one step ahead of our time. Many talk about sustainability. But the caring and sensitive handling of raw materials and the environment, especially in the plastics industry, is more important today than ever.

A question of HOW

It concerns HOW and WHAT is produced; for us it starts right at the beginning at our production sites. We take care to act in the most sustainable way possible at each point in time of the production. At the Austrian ALPLAindustrial plant, hydropower is the primary energy source. Production waste is fully resource-efficiently recycled.

More is achieved with less energy

We save energy where we can. That is one of our crucial strategic goals. Through targeted investments and process optimisations the energy requirement in all our plants is reduced in a sustainable way. 79 tonnes less in CO2 emissions: that is the gratifying result of the current ALPLAindustrial project whose goal is an increase in energy efficiency, a reduction of ongoing costs and all of that with low investments.

Resource optimisation and CO2-reduction

As a result of production and product improvements,

ALPLAindustrial is constantly optimising the raw materials

requirement for production. It also goes without saying

that CO2 reduction is a topic that we never disregard.

What makes us proud:

We received an award from the Austrian Ministry of the Environment for our successful energy efficiency measures. In this sense, ALPLAindustrial will also continue to try to be as goal-orientated in the future with regard to energies and raw materials.

Regeneration of plastics

In times in which the greatest efforts are being made, at all levels, to prevent harmful greenhouse gases, plastic recycling is making an important contribution to more climate protection. Through the replacement of new material (raw material fossil resources) by recyclate, considerable amounts of greenhouse gases are saved. The potential savings can amount to up to 2.2 kilogrammes of

CO2 for each kilogramme of recyclate that replaces the new material.

Cradle to Cradle – a brief overview:

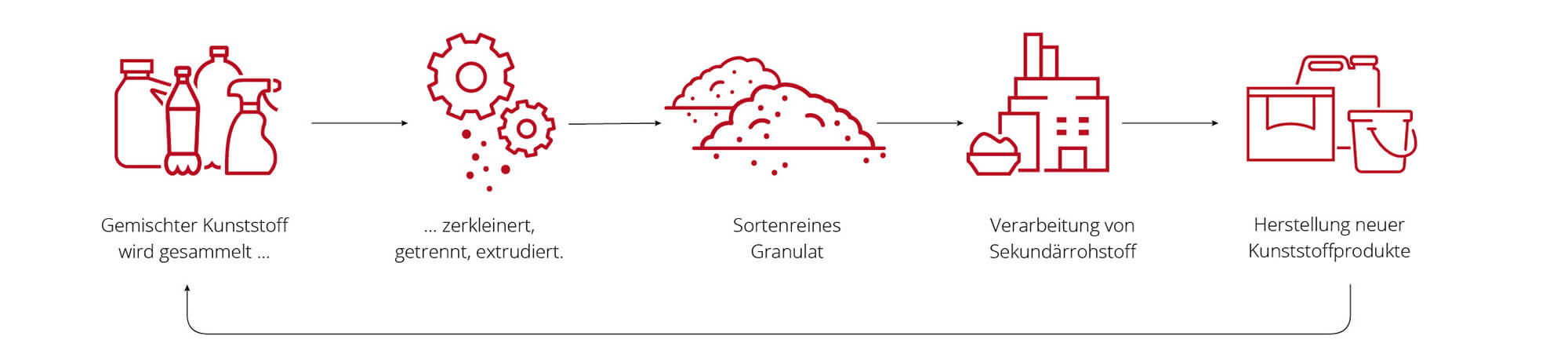

The cycle in full swing

ALPLAindustrial already put certain measures in place some years ago in respect of eco-efficiency; we wanted to think in terms of complete product cycles right from the start and in this way give rise to no waste at all in the conventional sense. Products should be manufactured in such a way that their end is considered right from the start. All used materials should be re-used after initial use.

Plastics are recycled externally, sorted according to type, and processed again at ALPLAindustrial. In doing so, products with a very high recyclable content (up to 100%) can be made.

Plastic with a past and a future

Certifications such as the Blue Angel eco-label contribute to consumer confidence. ALPLAindustrial is making great efforts to

gain as much certification as possible. The following criteria must be fulfilled in order to receive the Blue Angel eco-label: ❚ Post consumer-recycled plastics-in accordance with EuCertPlast Certificate ❚ PVC-free ❚ (Post-consumer) plastic recyclate content

in the finished product constitutes at least 80% by weight.

Giving packaging material value

Keeping an eye on the world also means always thinking outside the box. Here at ALPLAindustrial we are constantly giving thought to the general handling of plastic. One of the greatest challenges is to ensure that plastics do not enter the environment. Banning plastic is not the solution. It would be important to give packaging material a sense of value. In the general public, the perception prevails that metal has a value and that goes as far as copper piping being stolen. Plastic packaging must, therefore, be perceived as valuable.

Here, it is important to raise awareness among the population that will result in collected plastic being recompensed and, if need be, also in monetary value. That could ensure that plastic waste is not just carelessly thrown away to end up in the environment.

It continues on and on

In our sector, as far as the world is concerned, a definitive word is never spoken, because, time and again, there are new challenges which we must confront.

Here at ALPLAindustrial we are ready.